Notable Differences Between CNC Turning & CNC Milling

If you’re not explicitly familiar with the process, CNC turning and milling may seem the same; after all, they appear to be similar processes which achieve similar results. However, understanding the differences between CNC turning and milling will enable you to decide which method best fits the requirements of your particular project— potentially saving you […]

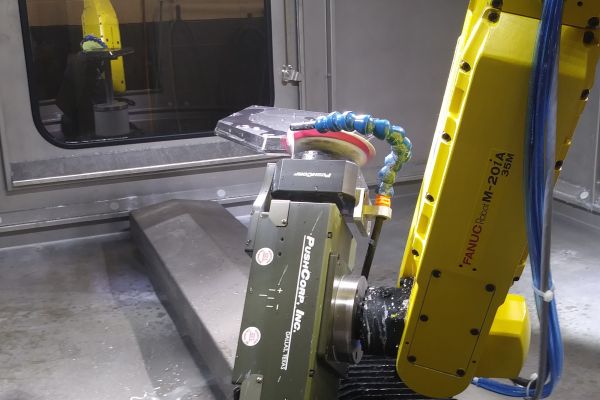

4 Measures to Improve Safety With Worker-Industrial Robot Collaboration in Manufacturing

Mitchell Machine has extensive experience integrating robotics with custom machinery, providing automation solutions in a variety of customer applications. With the recent technological development of force limited collaborative robots (a.k.a. co-bots), engineers can now safely deploy industrial robots in new ways. For instance, safety-monitored stop, hand guiding, speed, and separation monitoring, and power and force […]

What are the Costs Associated with Industrial Automation?

The newest wave of automation is driven by the same factors that first brought robotics and automation into the workplace: to perform highly complex tasks at a high rate of speed, while improving quality by eliminating errors and reducing variability. Automation also aims to cut manufacturing costs by replacing increasingly expensive people with more cost-effective […]

Tips for Purchasing Custom Automation and Process Equipment

Is your company forced to address issues caused by labor shortages, poor product quality, equipment downtime or spare part unavailability? Is the impending release of a new model or product forcing you to drastically modify your current manufacturing equipment. If you’re considering an investment in new automation machinery or custom process equipment, read through this […]

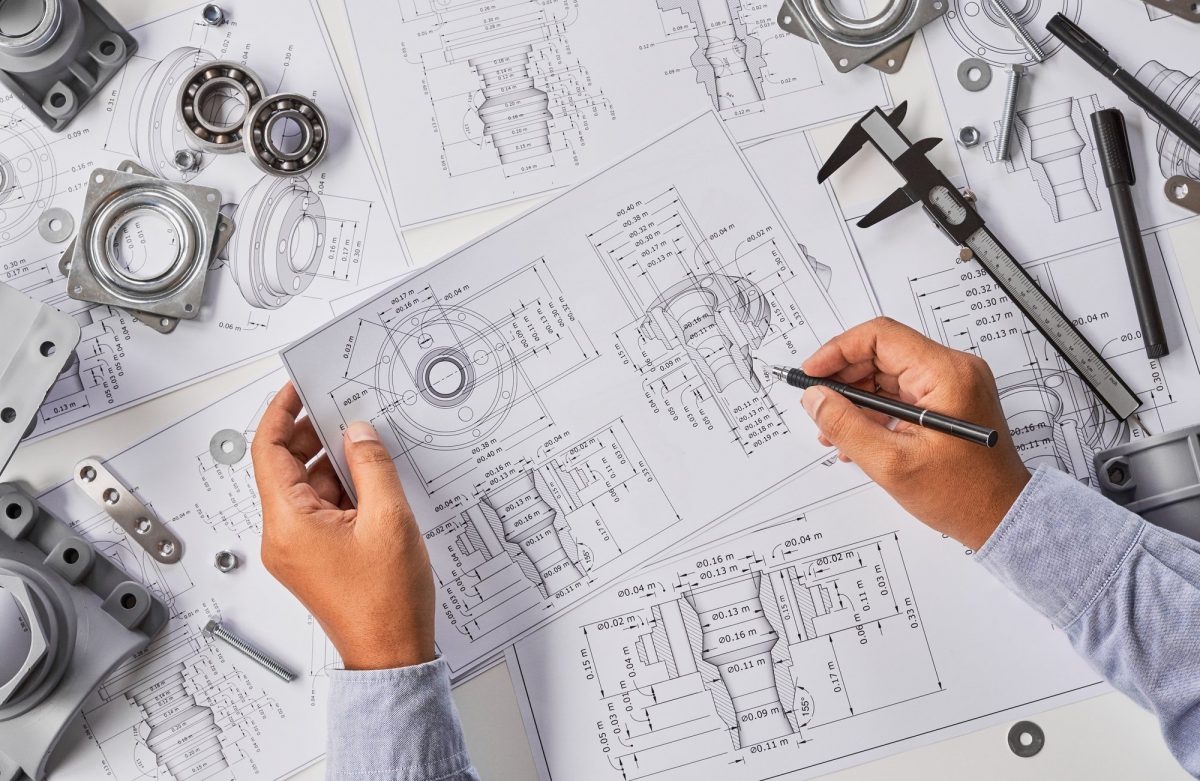

What are the Hidden Costs Associated with Surface Finish Specifications?

When designing a custom machined component it’s critical for the engineer to define all of a part’s characteristics— they must effectively communicate them to the machinist or fabricator. Typically, this is accomplished by creating an engineering drawing that contains numerical dimensions, defining the size and location fo every feature of the part. Beyond that, it […]

What are the Benefits Of Outsourcing Custom Machine Design & Build?

For 100+ years, Mitchell Machine, as a custom machine builder, has produced custom machine building projects to businesses in a wide variety of industries. Our machine-building capabilities range from focusing on building the full solution, to the initial design, or even the first batch and later assembly and installation. Businesses that are looking for specially […]

How to Obtain the Quickest Lead Times on Machined Parts Drawings

Engineering drawings are critical for communicating design intent for machined parts that require tight tolerances or other special requirements. Customers across a wide variety of industries attach drawings to their parts when requesting a quote. That being said, not all engineers are extensively trained on how to create great drawings that manufacturers will be able […]

3 Critical Factors When Choosing an Automation Integrator

Skilled automation integrators work diligently to apply cutting-edge thinking and technologies to your brand’s unique position. It’s essential to seek out an integrator with a steadfast commitment to developing and building the best automation system possible for your operational needs and your budget. Working with a versatile provider will ensure that they will be prepared […]

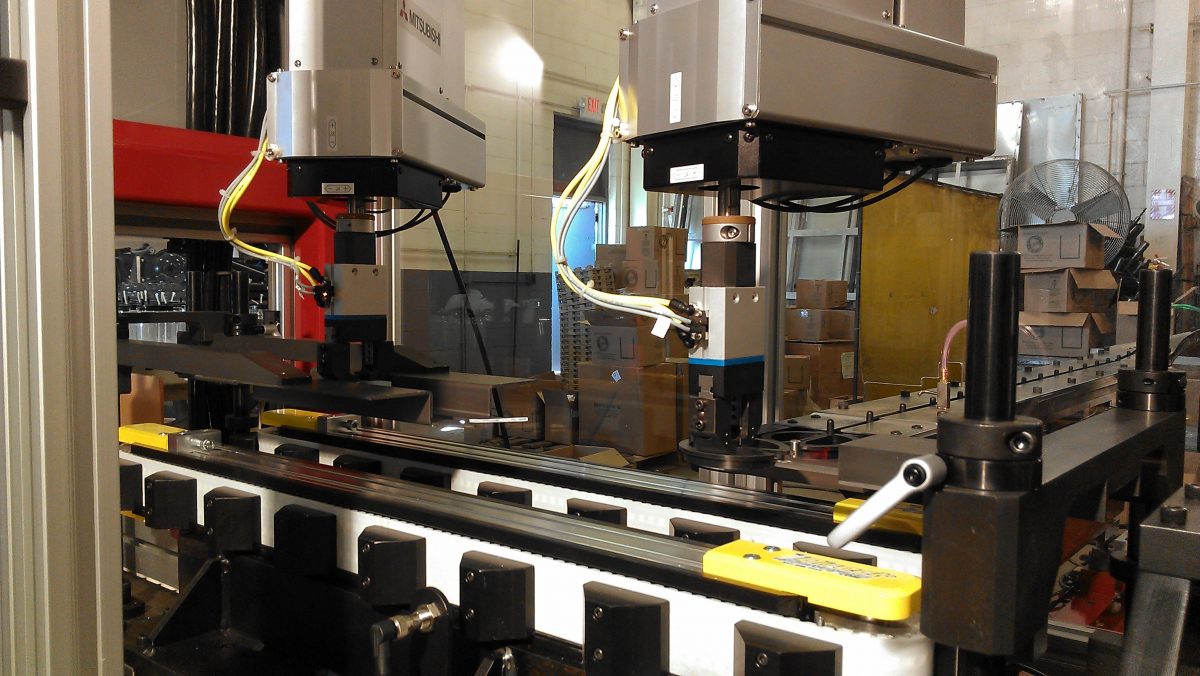

Increasing Manufacturing Output for a MRI Magnet Manufacturer

Our team successfully completed a 6-month design and build project to increase the manufacturing output for a MRI magnet manufacturer. The issue that was presented to MM was the need to increase manufacturing output while having a limited footprint to work with. The company had been experiencing great sales growth because of innovation that reduces […]

Which Factors Affect the Cost of CNC Machined Parts?

Different types of CNC machines, and their various unique processes, handle custom machining projects. That may not be surprising information; yet, what may be unclear is the major factors that impact the cost of machined parts. The time required to machine a part is directly affected by the design, materials, features, and tolerances. When you’ve […]