Menu

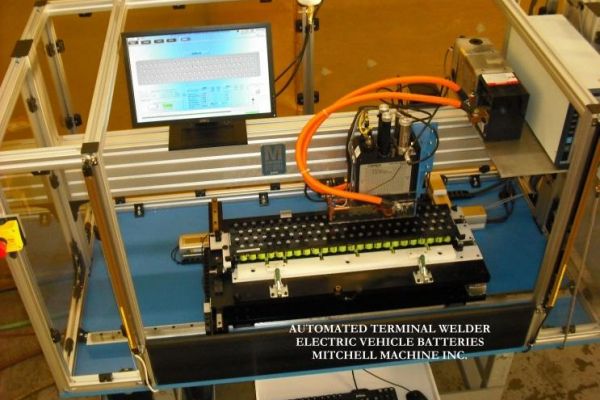

We can help you reduce design labor times and cost to improve manufacturing efficiency. Our team of automation experts knows the right balance between designing standard machines and equipment for efficiency and customizing to meet specific needs and requirements. Mitchell Machine industrial automation and control system designs are scalable building blocks used to save valuable time and resources. In addition, our designs are sustainable and flexible for multiple purposes.

Mitchell Machine can conduct a risk assessment during the design phase to help identify and mitigate hazards to help ensure compliance, improve safety, and avoid unnecessary redesign costs.

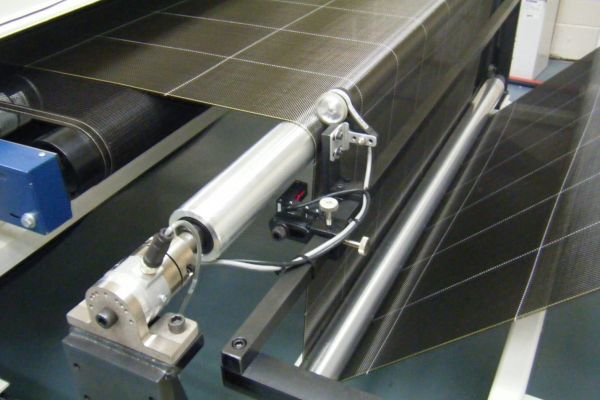

High strength and light weight Carbon Fiber Composites have become a mainstream material in automotive, sporting goods, and aerospace products. Mitchell Machine has been a leader in developing automated carbon fiber manufacturing systems for over 20 years, providing customers with industry leading equipment for manufacturing composite parts. Kevlar, Fiberglass and other materials are incorporated into the composites to achieve higher strength and special features.

Parallel processing, in process quality verification, and proper selection of work station components all lead to a successful integration project with near term payback.

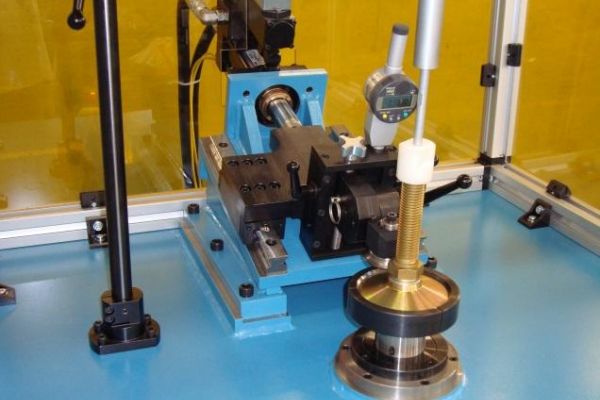

Our decades of machine building across many industries has given us a unique ability to integrate equipment to deliver the most utility for your investment. Snap fitting, fastening, pressing and adhesives are typical assembly processes performed.

Verification of assembly and product inspection by machine Vision, Laser sensors, leak testing, or other sub-systems are also typical in the automation Mitchell Machine delivers.